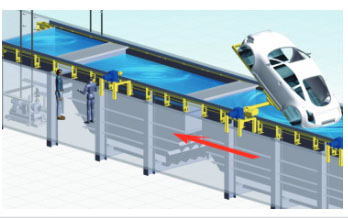

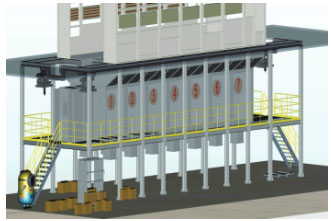

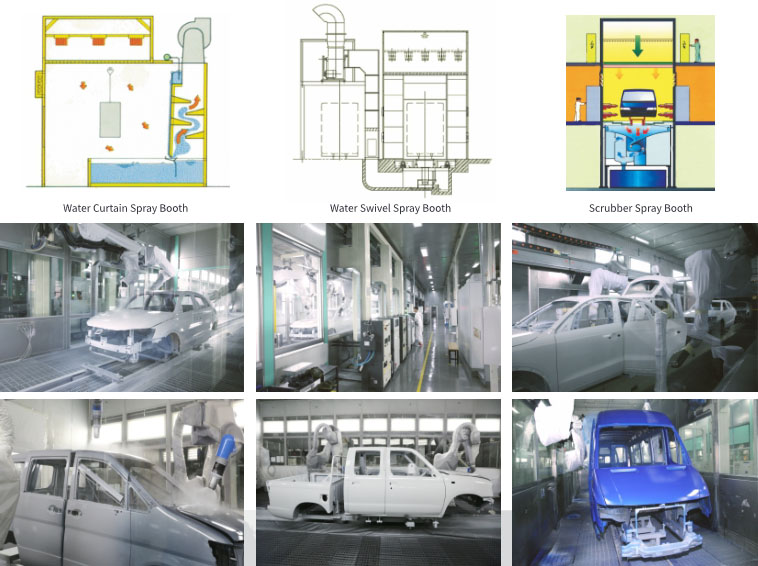

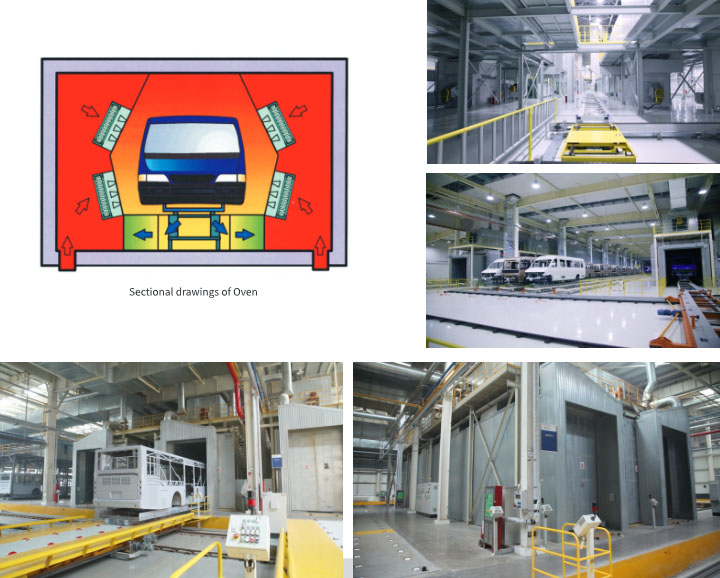

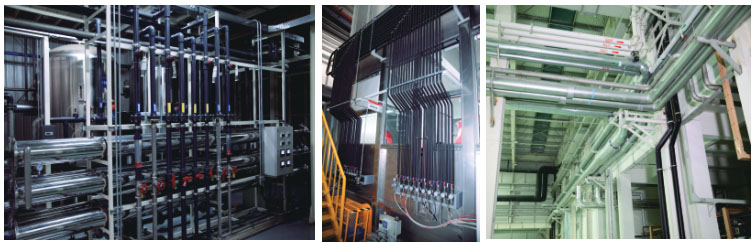

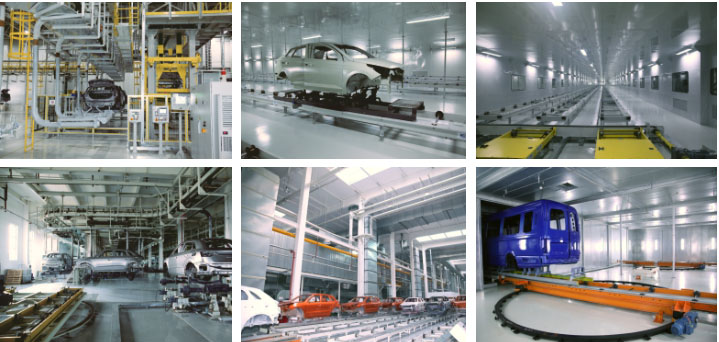

Based on customers’ products and process requirements, PINGYUAN could not only provide high-level systematic solutions for whole line from planning, designing, manufacturing, installing, debugging and other turn-key services, but also offer sub-systematic units, individual equipment and differentiated services, etc. Pretreatment equipment. Electrophoretic equipment. Painting Equipment, Oven Equipment, Pipeline system, Electric Control System.Air Conditioning System, Conveying System, Work Station Booth, Industrial robot system integration, Intelligent welding system. Technical transformation of equipment. Keep in-use. Cleaning service, etc.

PRETREATMENT EQUIPMENT

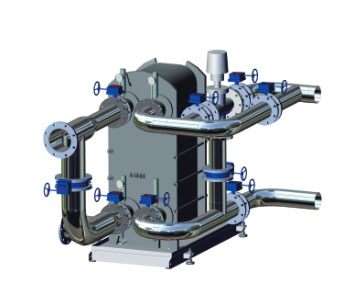

The duration and decorative effect of the coating is directly influenced by the pretreatment which is to get rid of the foreign matters on the surface to be applied and to supply an ideal basement qualified for the application as to assure the better anti-corrosion and decoration of the coating. Pretreatment mainly includes such techniques as Degrease, Rust Removal, Metering, Phosphate, Water Rinse and so forth, there being two types of pretreatment, Intermittent Step-transit Type and Successive Transmission Type, determined by the ways of the part’s movement.